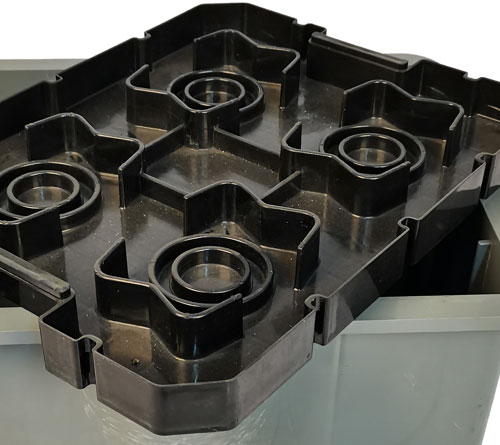

Tray for Automotive Parts

Product origin China Dalian

Injection molding is a machinery technology that is used for mass production of identical plastic parts with good tolerances. In injection molding , polymer particles melt firstly, then under the pressure injected them into the mold and cooling .Injection molding’s material is thermoplastic polymer that can coloring and add other additive. Every plastic parts are made by injection molding around you: from automatic parts to electric enclosure to kitchenware. Injection molding is so popular that because it has extremely low unit cost in mass production.

Advantages of injection mold:

1.Cost-effective

The cost of injection mold manufacturing is much lower and the design process is short and can be manufactured in large quantities in a short period of time that is compared with the traditional mold manufacturing process. Injection mold manufacturing isn’t only strong in quality and practicability, but the supply price is low and the service is good for injection mold manufacturing with high cost performance.

2.High quality

What prove common knowledge is that injection mold processing pays attention to the detail in process building and fully controls the material matching of the mold, at the same time , that has a high quality and is stable.

3.Multiple design types

Because the injection mold manufacturing’ each step is designed and disassembled separately, and various types of molds must be selected according to customer needs in the early stage. Therefore, the customers can choose the type and shape that is suitable for themselves in the required design and the manufacturer can also design and manufacture according to the needs of the customer. Injection molds have many types of choices and flexible designs that is compared with rigid molds.